If you flip your plastic bottle of Coca-Cola or Pepsi or Dasani over and look at the bottom, chances are you’ll see a triangle with the number ‘1’ inside it. This number corresponds with the recyclability code of PET or PolyEthylene Terephthalate, the plastic commonly used in bottles, jars, clear containers, and other food-holding devices. PET is known for its clear nature and food-safe properties, but it’s also the easiest to recycle plastic that’s commonly available… a feature the Polyformer uses to its advantage.

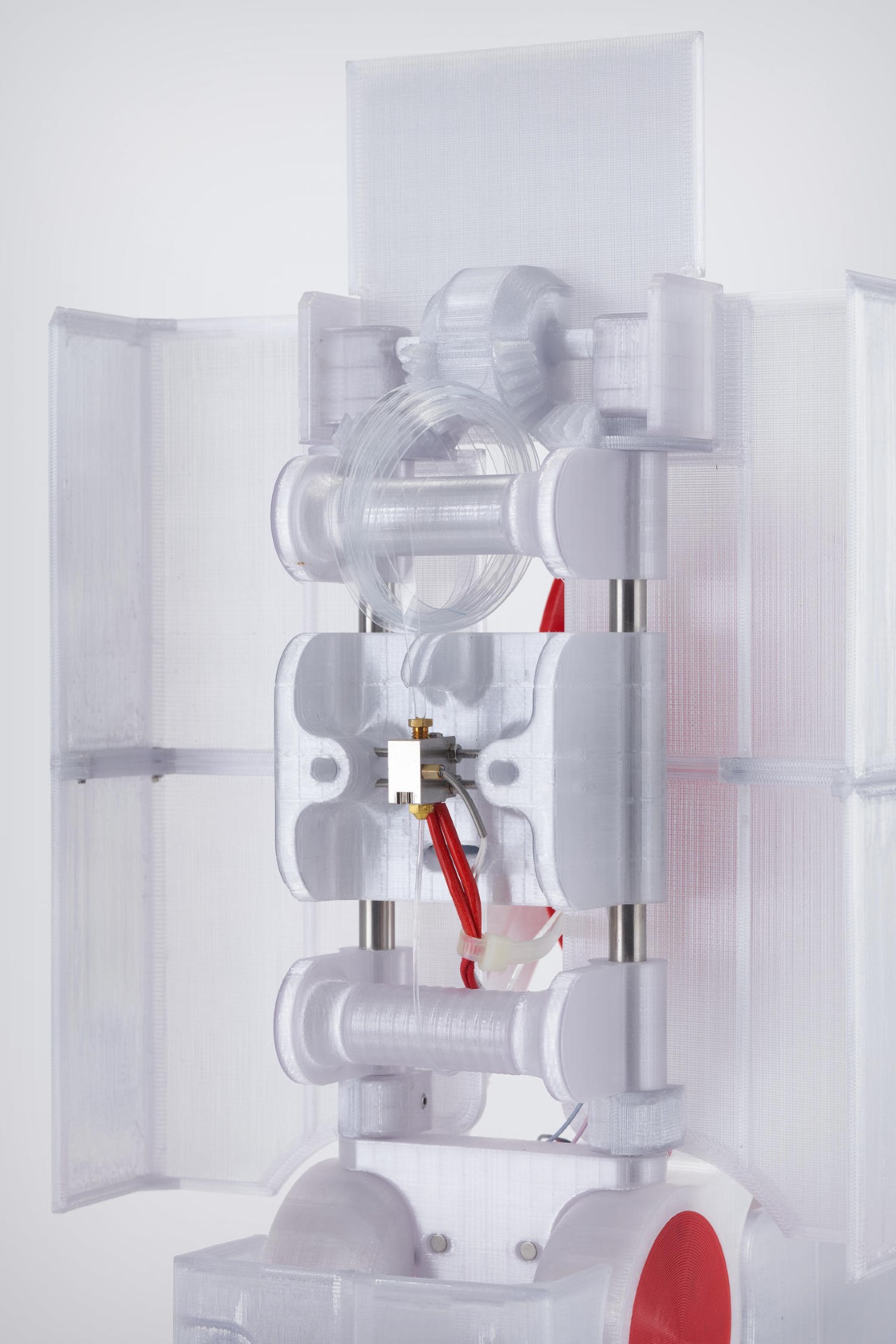

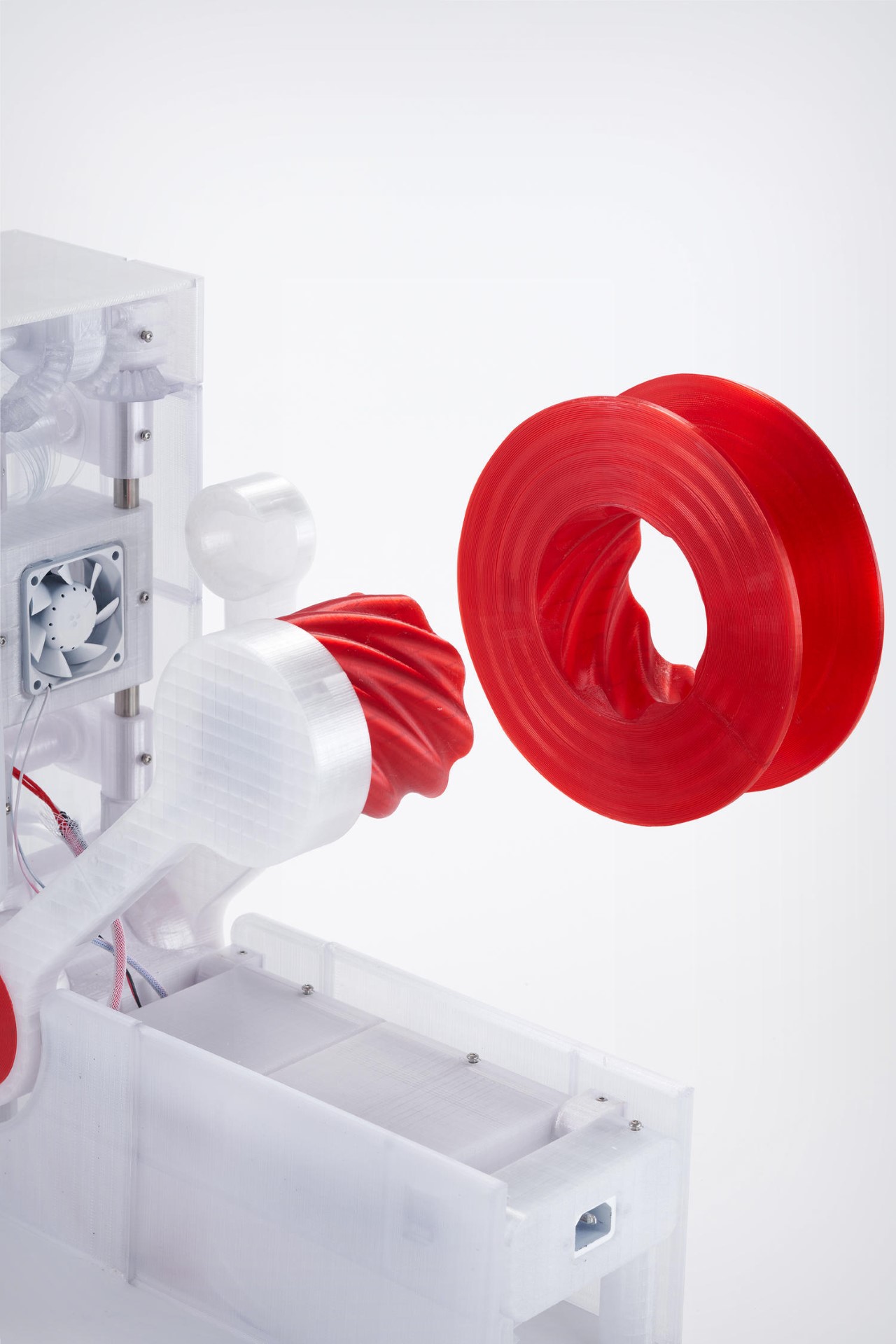

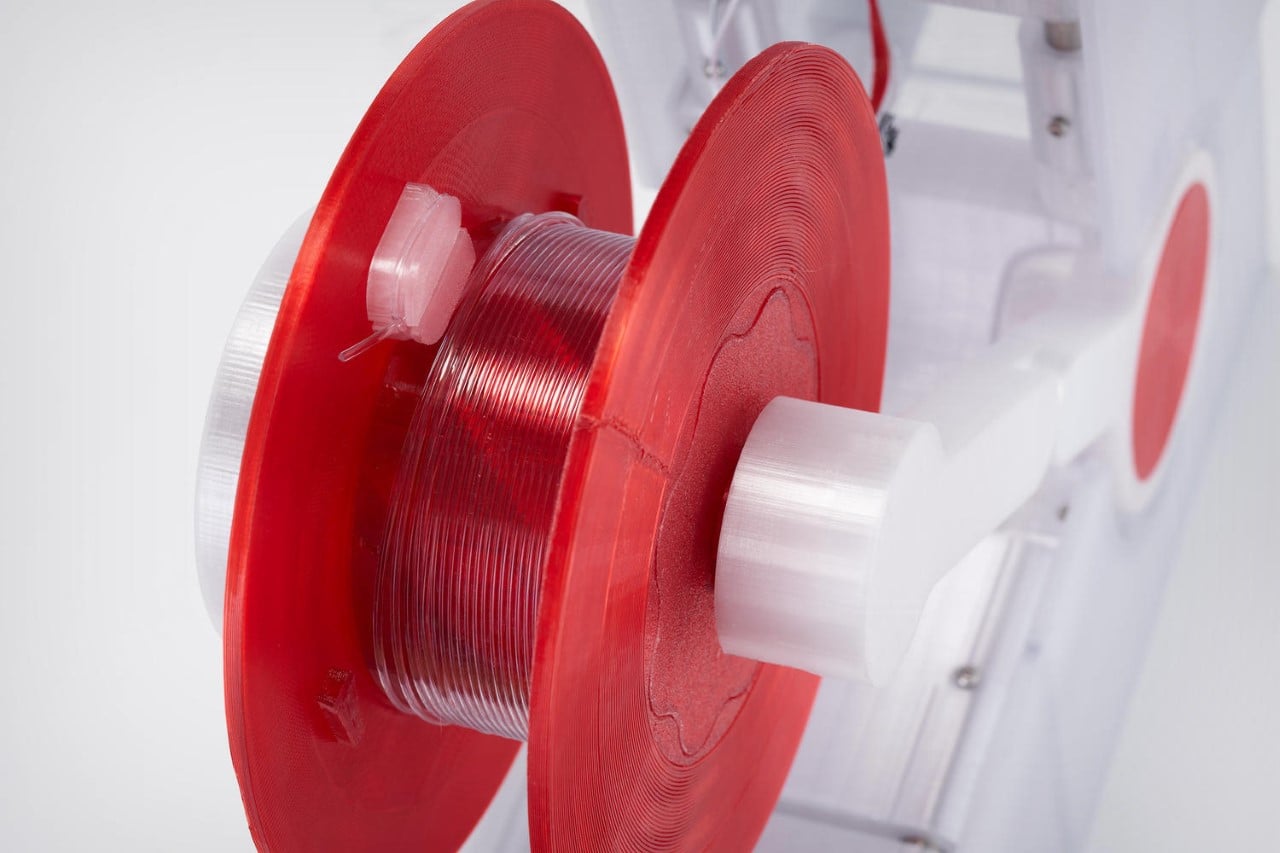

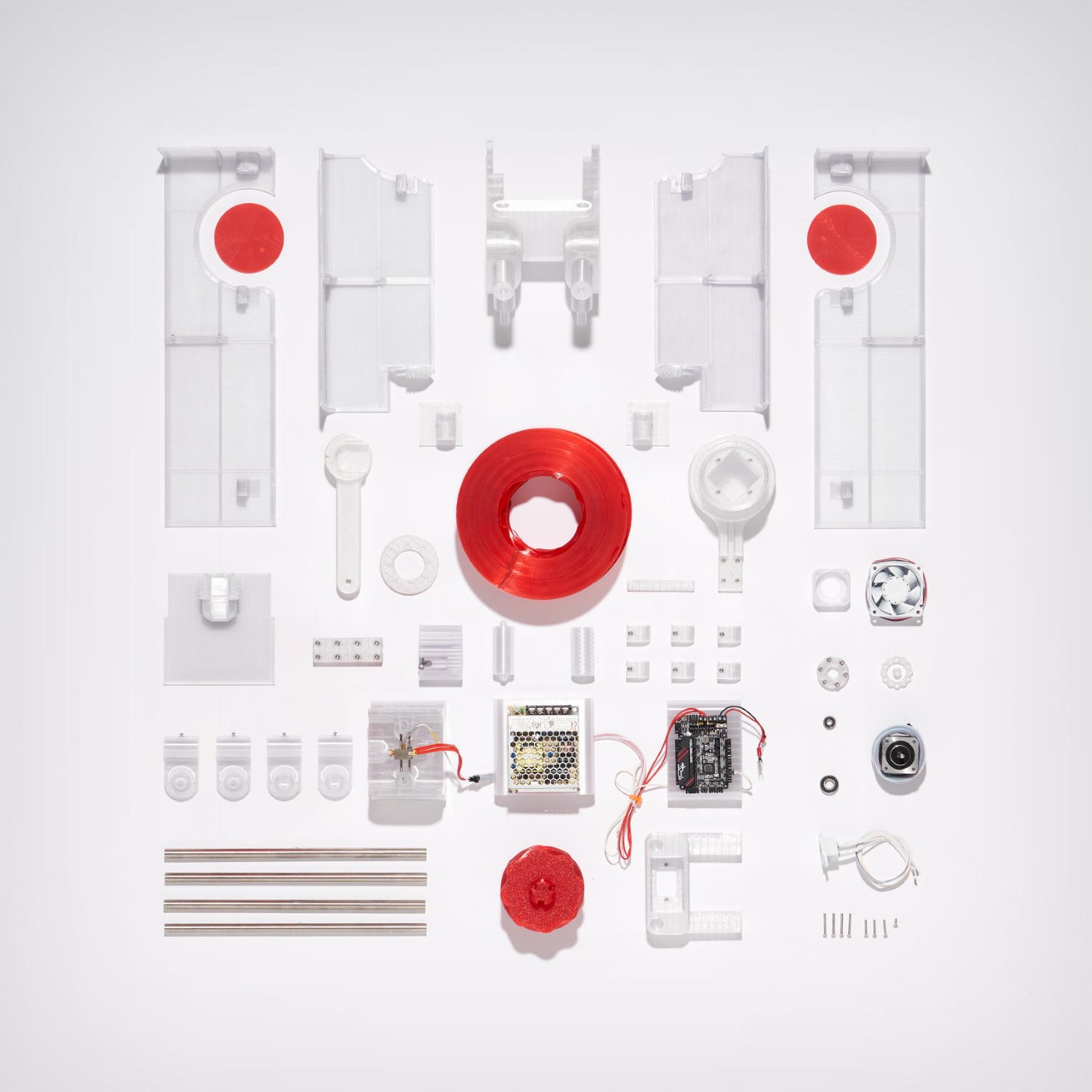

The Polyformer is a clever appliance that turns your waste plastic bottle into a clear 3D printing filament. It’s a cheap, compact, and open-source machine that cuts the bottle into a thin ribbon that gets melted and extruded into a filament. The filament is then wound around a spool, which can then be used by other 3D printers to print objects. The best part? A majority of the Polyformer’s design is made entirely from 3D printed parts too, acting like the perfect proof of concept!

Designer: Reiten Cheng

Click Here to view instructions on how to build your own Polyformer

Designed by Reiten Cheng, a student at the ArtCenter College of Design in California, the Polyformer is a simple product that anyone can build on their own with a few store-bought parts and a 3D printer. “The modular architecture allows users to easily swap out parts and modify the machine to their liking,” Cheng says. “The unique vertical L shape allows the users to interact easily with the machine and also minimizes the amount of space that the machine takes.”

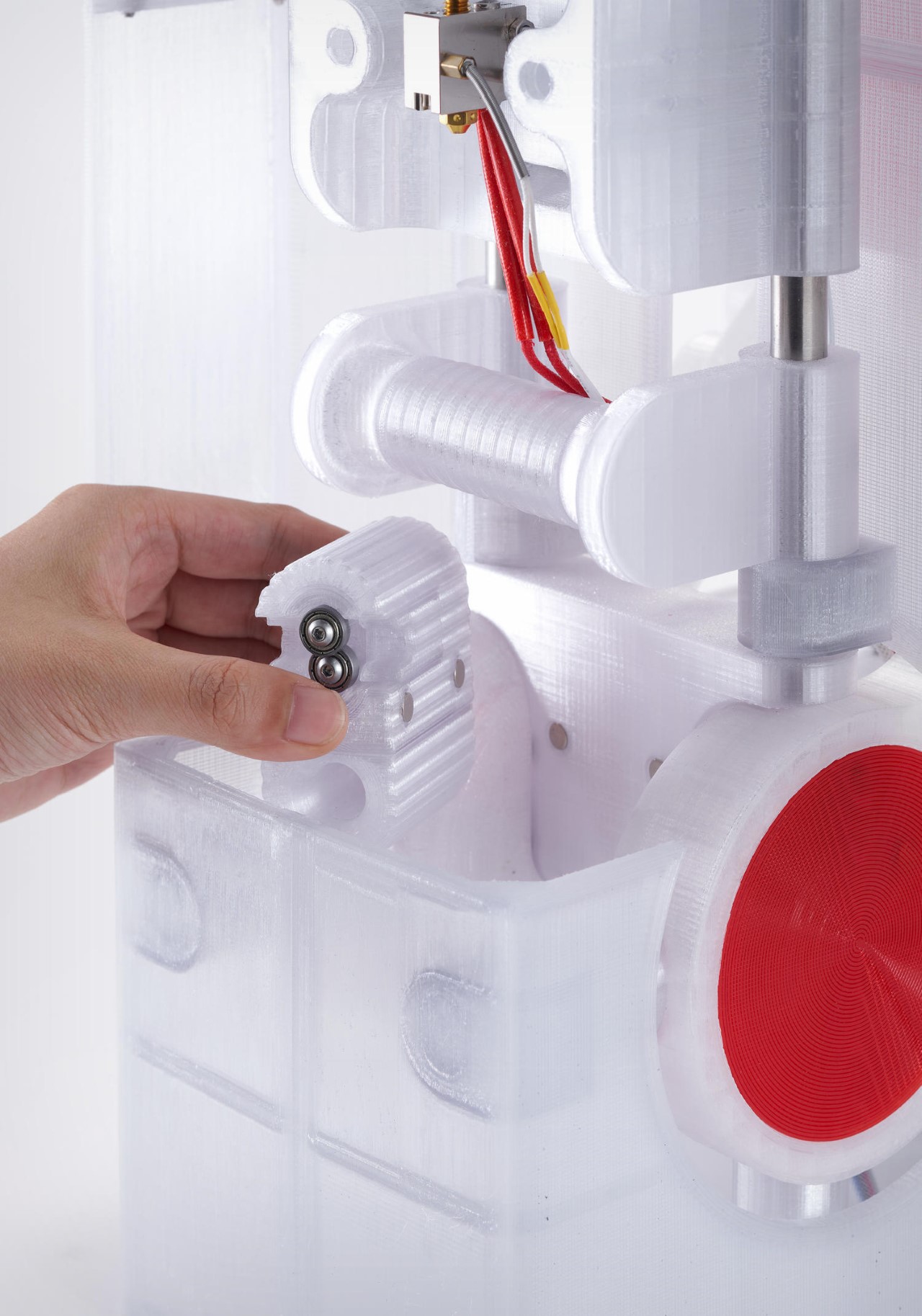

The Polyformer starts by stripping standard PET bottles into a uniform ribbon. Once the bottle’s been stripped away, the ribbon gets fed into a repurposed hot-end that uses a brass nozzle to extrude the melted plastic into a 1.75mm filament. The filament is then directed to the motorized spool, which rotates and collects it to be used later.

The entire product uses off-the-shelf parts and 3D-printed components. In fact, Cheng even open-sourced the Polyformer so that you can build your own. The files are available on the Polyformer GitHub page along with a detailed guide on how to assemble the device. Cheng’s website also mentions where you can buy off-the-shelf components like the aluminum heat block and the brass nozzle for the extrusion.

The Polyformer makes a unique pitch to help reduce plastic waste by practically giving plastic bottles a new life. This cradle-to-cradle approach is pretty much reinforced by the Polyformer itself, which Reiten printed out using 3D filament from recycled bottles, giving the entire appliance a beautiful translucent finish.

The Polyformer also went on to win multiple design awards like the James Dyson Award, the Core77 Award, and even secured 3rd place for the Hackaday Prize.

Click Here to view instructions on how to build your own Polyformer

The post Make Your Own 3D Printing Filament Using Recycled Plastic Bottles first appeared on Yanko Design.

No comments:

Post a Comment