Thinking of using natural materials in your project? Our latest Dezeen guide includes 12 types of biomaterials commonly used in architecture, design and interiors.

The term biomaterials is used to describe building materials derived from living organisms including plants, animals and fungi.

Plant-based materials, which we mostly focus on in this guide, are becoming increasingly popular among designers and architects due to their environmental performance.

This is because they offer cruelty-free production, are usually biodegradable and store CO2 during their useful lifetime, thereby lowering the embodied carbon footprint of buildings and products.

Some, like wood and hemp, can be used in their raw state while others such as algae, mycelium and food waste are generally mixed with other materials to be turned into useful composites.

Architects could "definitely" construct buildings completely out of biomaterials according to Biobased Creations CEO Lucas De Man, who told Dezeen that timber, hemp and mycelium could replace non-renewable materials like steel, plasterboard and cement.

Sequestering carbon is an important way to tackle climate change. Plant matter including algae, timber and hemp capture carbon from the atmosphere and transform it into biomass via photosynthesis.

With the recent focus on embodied carbon emissions, biomaterials are a "really exciting space", agreed Arup researcher and innovation leader Jan Wurm.

Read on to find out more about the most popular types of biomaterials and how they can be put to use.

Hemp is a type of cannabis plant that is grown for medicinal and industrial use. Unlike marijuana, it has very low levels of psychoactive THC.

Hemp grows extremely quickly and is "more effective than trees" at sequestering carbon, according to Cambridge University researcher Darshil Shah.

The plant's strong, stiff fibres can be processed into a variety of commercial goods including paper, textiles, bio-plastic, food and bio-fuel as well as industrial and construction products.

Mexico City design studio ATRA has used hemp-based fabric to upholster a sofa, while architecturally the hemp is most often processed into hempcrete.

This is formed from the woody inner part of the plant's stem, which is mixed with lime, water and sand to create a material that offers excellent thermal and acoustic insulation while acting as a carbon sink. An example of hemp used in buildings is Flat House in Cambridge (pictured), which was constructed using hempcrete panels.

Mycelium is the vegetative part of a fungus, made up of masses of branching, threaded shoots called hyphae that grow in soil.

The material can feed on low-grade agricultural waste and sequesters carbon stored in the biomass as it grows. Mycelium is fast-growing and can be cultivated in industrial bioreactors.

Sclerotia can be used to produce products including packaging such as Amen's candle packaging, as well as lampshades and furniture, as prototyped by Sebastian Cox and Ninela Ivanova.

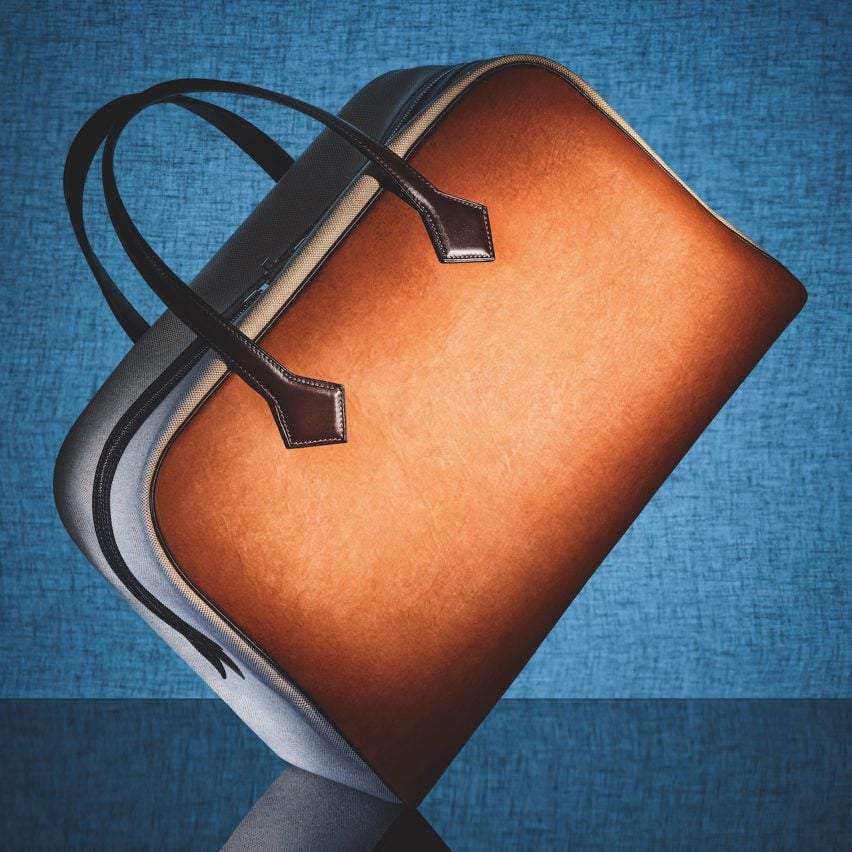

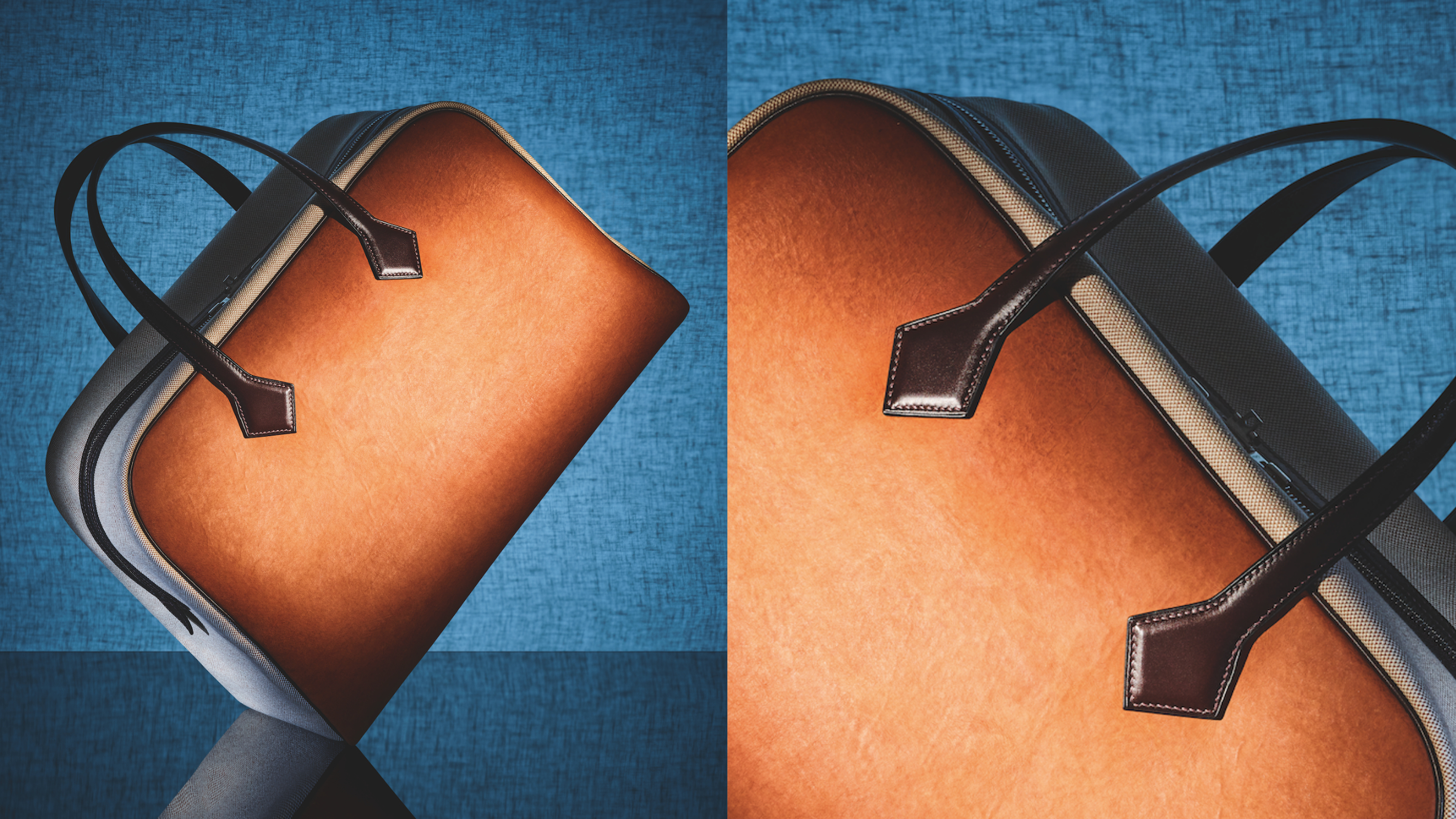

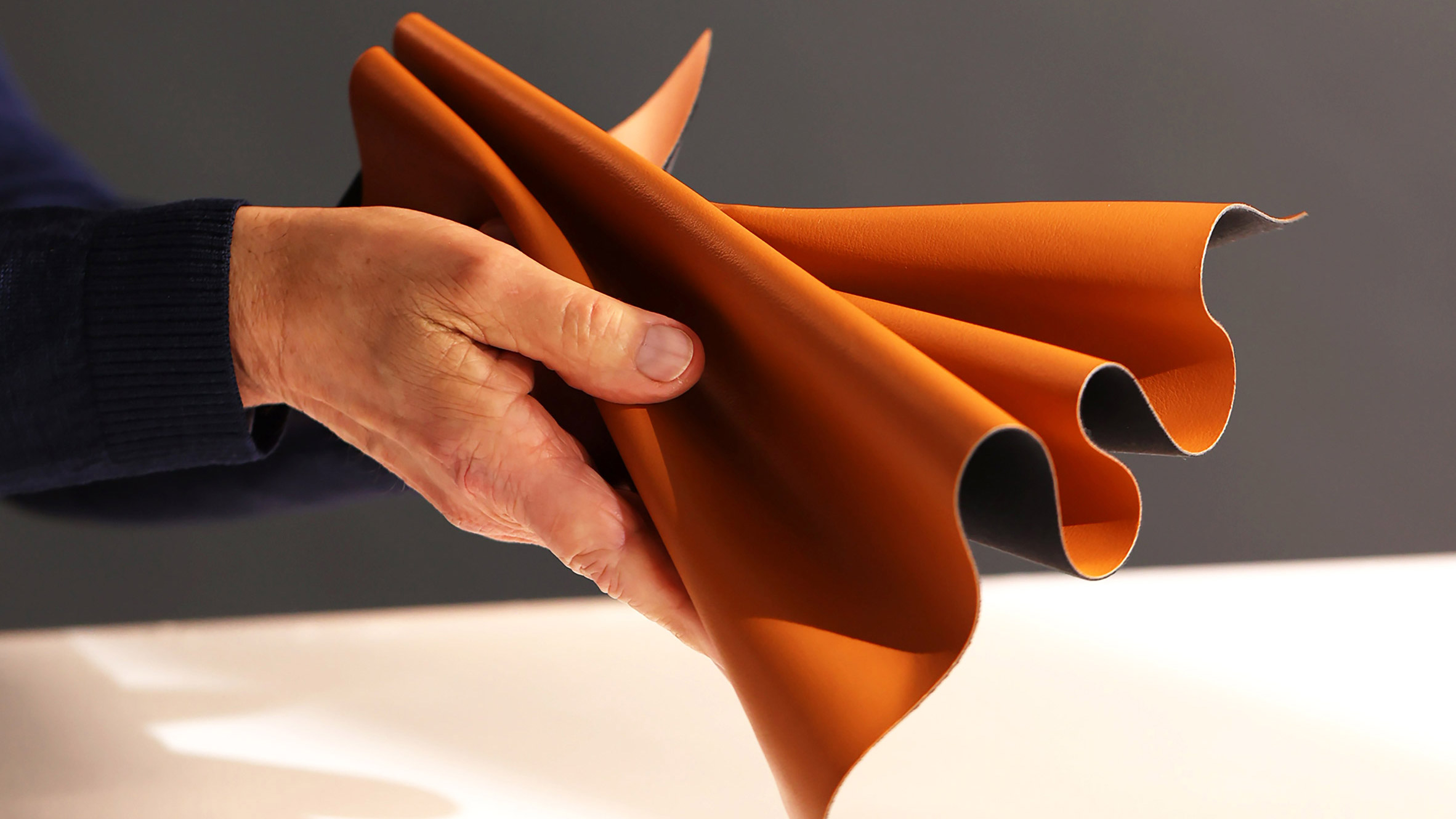

Mycelium's has proven to be extremely popular in the fashion industry as a leather alternative, with brands such as Stella McCartney, Adidas, Hermès and Kering investing in the biomaterial. Earlier this year, Hermès unveiled a partnership with MycoWorks, a biomaterials company, to reconceptualise its Victoria shopper bag (pictured) in a mycelium leather.

See projects featuring mycelium ›

Algae is an umbrella term for a group of photosynthetic organisms that mainly live in water. This includes seaweeds and kelp, which are the most important sources of oxygen in water and together are responsible for storing and sequestering more carbon than land plants.

Algae is often processed into bioplastic polymers, which can then be used as a replacement for fossil plastics.

The material has also been gaining popularity within the fashion industry for its use as a bioplastic. In 2019, Charlotte McCurdy created a raincoat using biopolymers entirely derived from algae. The industrial designer later collaborated with fashion designer Philip Lim to create a dress covered in algae bioplastic sequins (pictured).

See projects featuring algae ›

Chitin is a fibrous substance that forms the exoskeleton of crustaceans and certain insects, as well as the cell walls of fungi.

The material is the world's second-most abundant biopolymer. But to use chitin, it must be chemically extracted before being processed into a useable material.

Due to the difficult extraction process, commercially available versions of chitin such as chitosan are typically expensive. In reaction to this, four designers from the Royal College of Art and Imperial College developed a number of machines that extract and turn chitin into a bioplastic.

See projects featuring chitin ›

Wood is a renewable material that offers a low-carbon alternative to concrete and steel. Due to its highly machinable, lightweight structural tissue, which is strong yet flexible, wood has historically been used to construct furniture and products as well as small houses.

Recent advances in engineered timber, also known as mass timber, has allowed the material to be used at larger scales, with Voll Arkitekter building the world's tallest timber building, a 53-metre-high tower in Norway (pictured).

In the world of product design, Yves Béhar combined sawdust mixed with tree-sap to create 3D-printable homeware while Carlo Ratti Associati designed a concept for a compostable marker pen that would be made from a choice of biodegradable materials including wood.

Although commonly mistaken as a type of tree, bamboo is actually a grass. Bamboo is the fastest growing plant on the planet, making it both affordable, rapidly renewable and capable of sequestering large amounts of carbon.

Its canes lend themselves to creating light, flexible structures that can resist natural disasters such as earthquakes and hurricanes.

Architecture studio Vin Varavarn used bamboo to build an agricultural learning centre in Thailand, while Music electronics brand House of Marley used the plant to make wireless earbuds (pictured) that are an "eco-conscious alternative" to plastic earphones.

See projects featuring bamboo ›

With awareness about the emissions and animal cruelty associated with large-scale cattle farming, leather alternatives are increasingly rising in popularity.

These are typically made using renewable biomass sources such as vegetable and food waste. But some designers have also used waste from industrial agricultural processes to produce their materials.

There are currently a vast number of vegan and leather alternatives including mycelium leather Mylo and Leap (pictured), which is made from waste apple cores and skins from the production of cider and apple juice.

A vegan leather by Tjeerd Veenhoven was created from the leaves of the area palm and has similar qualities to Piñatex, a leather alternative made from pineapples. Vietnamese designer Uyen Tran created a leather alternative from waste coffee grounds and chitin. The material, which was titled Tômtex can be embossed to replicate a variety of animal leathers.

See projects featuring leather alternatives ›

Bioplastics are polymers derived from biological and renewable sources as opposed to plastics made from fossil fuels.

Polylactic acid (PLA) is the most common bioplastic. It is typically made using corn starch or sugar cane. PLA is widely used as printable filament in 3D printers, where PLA filament is fed through the printer and melted at high temperatures to create a malleable substance that is printed into the desired form.

Design Studio Ammunition and light company Gantri 3D-printed PLA to create wall sconces and lamps. Another example of PLA-based products is Studio RYTE's biodegradable Triplex, which is made from flax fibres mixed with PLA.

Other bioplastics include MarinaTex (pictured), a single-use material that is made from key ingredients including fish scales and skin, which was designed by British designer Lucy Hughes.

See projects featuring bioplastic ›

Linoleum is a biodegradable material made from plant-based materials including linseed oil, pine resin, cork dust and sawdust. The material is typically used as a floor covering due to its durable and resistant characteristics.

The material was first patented in 1860 when rubber manufacturer, Fredrick Walton discovered linseed-based paint formed a tough and flexible film on its surface. Most Linoleum today is derived from linseed oil, which is extracted from flax seeds and then mixed with materials such as cork and wood dust.

In 2018, designer Don Kwaning developed Lino Leather from a series of experiments using linoleum. Kwaning created two materials that emulate leather of different structures, thicknesses and textures.

MSDS Studio added speckled linoleum furniture to the interior of a Toronto flower shop (pictured). A large island and shop counter were wrapped in the material for its affordable and humble qualities said the designers.

See projects featuring linoleum ›

Cork, which is gathered from the outer bark of the cork oak tree is a popular material among designers and architects due to its compostable and easily harvestable qualities. Cork House used sustainably-sourced, cork blocks to build its five-volume structure which was supported by timber components.

The Cork Studio is a garden building that is made almost entirely out of cork. The structure was constructed by Studio Bark as a building prototype that can be completely recycled, reused or composted.

French designer Noé Duchaufour-Lawrance used the discarded material to create a furniture collection of amorphous forms and a range of different textures.

Straw is an agricultural byproduct that is comprised of the dry stalks of cereal plants after the grain has been harvested. The material is often used in construction and offers homes a renewable, biodegradable form of insulation. LCA Architetti used straw as insulation within the walls of The House of Wood, Straw and Cork (pictured).

The Exquisite Corpse is a collection of marquetry that comprises three handmade furniture pieces decorated with straw that was dyed vibrant, colours.

See projects featuring straw ›

Cellulose is a structural compound typically found within the cell walls of green plants, the material can be extracted from a variety of plants including trees, often being used to create fibres. Swedish label Kön produced a range of gender-neutral underwear that was made from plant-based cellulose.

Barcelona-based startup Hontext developed a construction board material that is derived from a combination of enzymes and cellulose (pictured) sourced from waste streams of paper production. The fibres are saved from going to landfills or being burnt and turned into construction boards to be used for interior partitioning or cladding.

Anna Piasek created a modular takeaway food packaging that can be sub-divided into smaller sections to accommodate multiple dishes. The packaging was made from moulded cellulose, that was pressed into shape using a metal mould and then dried in an oven and coated.

See projects featuring cellulose ›

The post The Dezeen guide to bio-based materials in architecture, design and interiors appeared first on Dezeen.

No comments:

Post a Comment